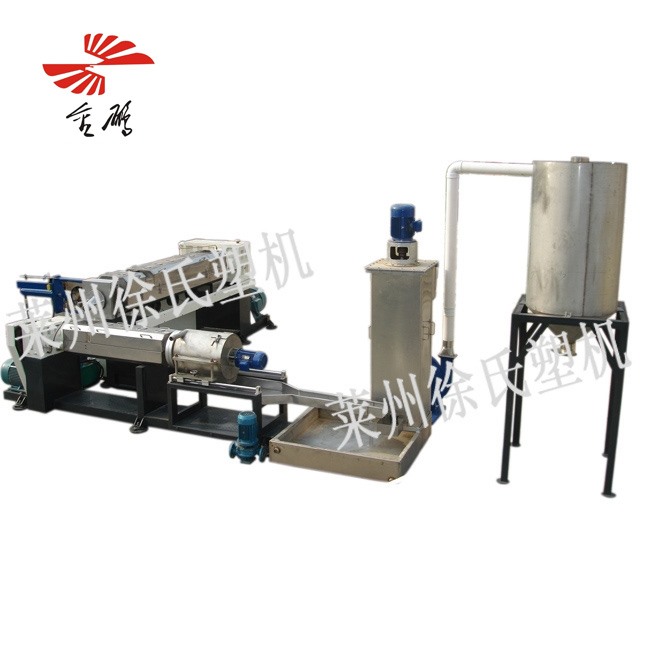

Plastic granulation production line

Overall solution provider

Laizhou Xushi Plastic Machinery Co., Ltd. supplies all kinds of plastic machinery, plastic granulator and plastic crusher for a long time.

This type of plastic granulator is a high configuration unit, which is more suitable for the regeneration and granulation of waste plastics than the previous single machine model, and more suitable for the types of plastics. It is mainly used for processing waste plastic film (industrial packaging film, agricultural plastic film, greenhouse film, beer bag, handbag, etc.), woven bag, agricultural convenience bag, basin, barrel, beverage bottle, furniture, daily necessities, etc., and is suitable for In most of the common waste plastics, it is the most widely used, most widely used and most popular plastic recycling processing machinery in the waste plastics recycling industry.

The surface finish of waste plastics with water is higher after manufacturing finished particles, and the porosity of particles is lower after two times of step exhaust, and the output is about 10% higher than that of the same type of unit. After the main engine is equipped with hydraulic screen changing die head, the unit can achieve the advantages of no shutdown, continuous strip, no manual work, no machine head under corner material can be used continuously, etc

This machine can also choose the automatic feeding machine designed and produced by our factory, which can realize the one-stop production of automatic conveying, feeding, plasticizing, exhausting and extruding. The unit can be placed in "one" type and left and right "t" type, which saves space and has more relaxed requirements for the workshop.

| Model | SJ110-125型 | SJ125-150型 | SJ150-180型 | SJ175-200型 | SJ200-220型 |

| Main screw diameter | 125mm | 150mm | 180mm | 200mm | 220mm |

| Spindle speed | 65rpm | 65rpm | 65rpm | 62rpm | 62rpm |

| Main motor power | 18.5kw | 30kw | 55kw | 75kw | 90kw |

| Heating power | 14kw | 19kw | 27kw | 32kw | 40kw |

| Yield | 110-150kg/h | 150-180kg/h | 200-230kg/h | 250-280kg/h | 300-350kg/h |

| Boundary dimension | 2.2*1.25*0.79m | 2.84*1.62*1.1m | 3.31*2.2*1.2m | 4.47*2.68*1.54m | 6.4*3.23*1.62 |

| Machine weight | 3.3T | 4.4T | 5.7T | 6.9T | 7.2T |

| Model | SJ110-125型 | SJ125-150型 |

| Main screw diameter | 125mm | 150mm |

| Spindle speed | 65rpm | 65rpm |

| Main motor power | 18.5kw | 30kw |

| Heating power | 14kw | 19kw |

| Yield | 110-150kg/h | 150-180kg/h |

| Boundary dimension | 2.2*1.25*0.79m | 2.84*1.62*1.1m |

| Machine weight | 3.3T | 4.4T |

| Model | SJ150-180型 | SJ175-200型 | SJ200-220型 |

| Main screw diameter | 180mm | 200mm | 220mm |

| Spindle speed | 65rpm | 62rpm | 62rpm |

| Main motor power | 55kw | 75kw | 90kw |

| Heating power | 27kw | 32kw | 40kw |

| Yield | 200-230kg/h | 250-280kg/h | 300-350kg/h |

| Boundary dimension | 3.31*2.2*1.2m | 4.47*2.68*1.54m | 6.4*3.23*1.62 |

| Machine weight | 5.7T | 6.9T | 7.2T |

Contact us

Address:Luwang Industrial Park, Shahe Town, Laizhou City, Shandong Province

Tel: 0535-2348057

E-mail:info@sd-pengcheng.com

Product Center

Product Center

Product Center

Mobile website